Precision Machined Components for Medical Device Manufacturers

ORRCO provides precision machining for medical devices and surgical instruments, with over 80 years of experience producing tight-tolerance components for the healthcare industry.

Our Capabilities for Medical Device Manufacturers

Our ISO 9001:2015-certified facility in Greensburg, Pennsylvania provides medical device manufacturers with the quality infrastructure, traceability, and dimensional accuracy their applications demand. We machine complex, multi-feature components from a wide range of biocompatible and medical-grade materials with tolerances as tight as ±0.0001 inches.

- ISO 9001:2015 certified quality management system

- Tight tolerances — down to ±0.0001 inches

- In-house ultrasonic cleaning for contamination-free parts

- Comprehensive inspection and dimensional reporting

- Stable, repeatable production across high-volume runs

- Material traceability and documentation

What We Bring to Medical Manufacturing

Medical device manufacturers choose ORRCO because our core capabilities align

with what the industry demands — tight tolerances, clean parts, documented

quality, and consistent repeatability.

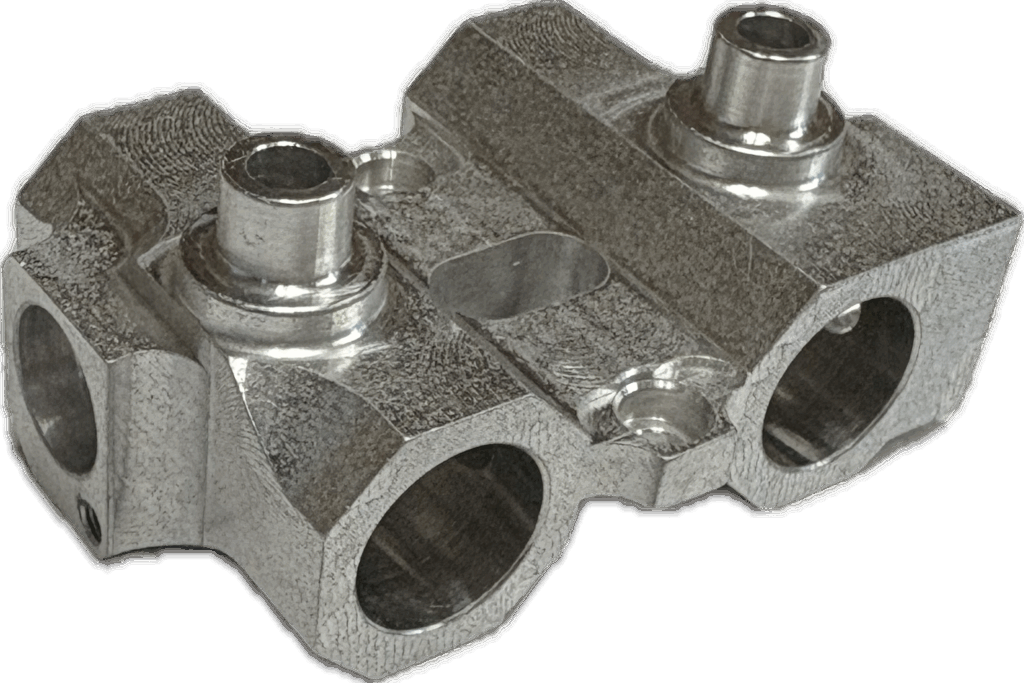

We produce precision machined components including valve bodies and fluid

control parts, custom fasteners and connectors, housings and enclosures,

and other tight-tolerance components used in medical equipment and devices.

Every part is produced to your exact drawing and specifications.

If you’re evaluating ORRCO as a supplier for your medical application,

we welcome the conversation. Share your drawing and requirements and we’ll

give you an honest assessment of fit and a competitive quote.

Materials for Medical Machining

- Stainless Steel (303, 304, 316L) — corrosion-resistant, sterilizable

- Aluminum (6061, 7075) — lightweight structural components

- Brass — connectors, fittings, and fluid handling parts

- Engineering Plastics — PEEK, Delrin, and other medical-grade polymers

Quality You Can Document

In medical device manufacturing, quality isn’t just about the part — it’s about the process. ORRCO’s ISO 9001:2015 quality system ensures that every step of production is controlled, monitored, and recorded. We provide dimensional reports and work closely with OEM quality teams to meet their specific documentation requirements.

Our in-house ultrasonic cleaning capability ensures your components are delivered free of chips, oils, and particulate — ready for your assembly or sterilization process.

Medical manufacturers trust ORRCO for precision machining for medical devices because we combine decades of experience with a quality system built for the demands of the healthcare industry. Every component we produce is treated as critical — because in medical applications, it is.

Why Choose ORRCO for Precision Machining for Medical Devices

- 80+ years of machining experience — we’ve seen and solved the hard problems

- Scalable production — from short validation runs to full-volume production

- Responsive team — direct communication with the people running your parts

- Consistent quality — same quality, same results, run after run

From our ISO 9001:2015 certified facility in Greensburg, PA, we serve medical device manufacturers across the United States and internationally — providing the precision, cleanliness, and documentation that healthcare applications demand.

Request a Quote for Medical Machined Components

Tell us about your component requirements and we’ll provide a fast, accurate quote. We work with engineering teams during design review to optimize parts for efficient, cost-effective production.