A Legacy in Every Metal Chip: Preparing to Celebrate 80 Years of Precision Manufacturing

December 12, 2025CNC Machining Materials: How to Choose Between Steel, Aluminum, and Brass

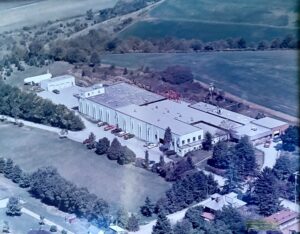

February 18, 2026Celebrating 80 Years of Precision Machining at Orrco

Few companies reach the milestone of eight decades in continuous operation. This January, Orrco celebrates its 80th anniversary—an achievement that reflects not only longevity, but an unwavering commitment to precision, quality, and partnership.

As a third-generation, family-owned manufacturer, Orrco offers something increasingly rare in today’s supply chain: the stability of time-tested craftsmanship paired with the advanced capability of modern CNC technology. Over 80 years, we have evolved strategically to serve as a single, trusted source for everything from high-volume production to complex, tight-tolerance components.

The Heritage: Three Generations of Commitment

Orrco’s story began in 1946, founded on the simple, powerful idea that American industry demanded reliable, high-volume precision parts. Our founder, Tom M. Orr., established the earliest standards of excellence using dependable screw machines, cementing our reputation in the post-war era.

Orrco’s story began in 1946, founded on the simple, powerful idea that American industry demanded reliable, high-volume precision parts. Our founder, Tom M. Orr., established the earliest standards of excellence using dependable screw machines, cementing our reputation in the post-war era.

-

-

-

- The Second Generation – Tom M. Orr’s sons, Tom and Keith Orr, recognized the accelerating pace of technology, strategically investing in the very first CNC machines and custom rotary transfer machines in the 1980s. They embraced the future while honoring the high-volume efficiency of our past.

- The Third Generation – Keith Orr’s daughters, Kelly McCambridge and Kathleen Orr, continue this legacy today. They are actively driving investments in multi-axis automation, digital quality control, and lean manufacturing processes.

- The Second Generation – Tom M. Orr’s sons, Tom and Keith Orr, recognized the accelerating pace of technology, strategically investing in the very first CNC machines and custom rotary transfer machines in the 1980s. They embraced the future while honoring the high-volume efficiency of our past.

-

-

This family-led leadership ensures lasting relationships built on trust and experience.

The Foundation: The Enduring Art of Multi-Spindle Screw Machining

The bedrock of our history lies with the multi-spindle screw machine. For decades, the high-volume production of brass, steel, and aluminum components required the intricacy of cam changes and manual tooling adjustments. While many processes are now digitized, our mastery of these machines remains a core technical advantage.

The Multi-Spindle Advantage Today:

The inherent efficiency remains unmatched for high-volume orders. For parts that power industries from automotive to fluid control, where consistency across millions of units is mandatory, our decades of mastery translate directly into:

- Superior Efficiency: Performing multiple simultaneous operations for the highest throughput.

- Cost Optimization: The most economical production method for large quantities.

- Proven Repeatability: Eight decades of knowing how to make the 10,000th part as precise as the first.

The Evolution: Mastering Multi-Axis CNC Mill-Turn

The greatest strategic shift in our history was the transition to complex CNC machining. This leap required significant capital and re-skilling of our workforce – a major undertaking for any family business. Today, our sophisticated CNC Bar machines are the proof of that vision, allowing us to produce components for critical applications like medical devices and aerospace assemblies.

The Technical Leap

| Manufacturing Attribute | Multi-Spindle Screw Machines | CNC Mill-Turn Centers |

|---|---|---|

| Best Application | High-volume, repeatable production | Complex, low, mid, and high volume components |

| Setup Strategy | Optimized cam-driven setups for long runs | Single-setup, multi-axis flexibility |

| Cost Efficiency | Lowest cost per part at high volumes | Cost-effective for complex geometries |

| Tolerance Capability | Excellent and highly repeatable in production | Extreme precision to tight tolerances |

| Geometry Strength | High-speed precision turning | Complex contours, cross-holes, threading |

| Ideal Use Case | Millions of identical parts | Highly engineered components |

Orrco maintains both multi-spindle screw machines and CNC bar machines because each excels in different manufacturing scenarios. Precision is not about the newest machine. It is about using the right technology for the part.

The Orrco Differentiator: Stability and Service

Our 80 years in business is more than just a historical marker—it’s a commitment to stability that strengthens your supply chain and mitigates risk.

- Navigating Economic Cycles: We have successfully managed through multiple recessions, inflation spikes, and supply chain disruptions over eight decades. We know how to maintain consistent operation and pricing stability where others cannot.

- Comprehensive Value-Add: Our service extends beyond cutting metal. We offer seamless automated secondary machining, deburring, cleaning, and assembly, providing ready-to-use components and simplifying your procurement process.

- Consulting Partnership: Decades of machining every type of material and geometry means our engineering team provides invaluable Design for Manufacturability consulting, ensuring your design is optimized for performance and cost-efficiency before production starts

The Next Chapter

As we celebrate our 80th anniversary, we are not dwelling on the past. We are focused squarely on the future, continuing to invest in process automation, smart manufacturing initiatives, and the next generation of highly skilled machinists.

Our 80 years of experience proves one thing: Orrco is built to last, and built for precision.

Ready to partner with 80 years of machining expertise?

Contact us today to request a custom quote for your next high-volume screw machine run or complex CNC Mill-Turn component.