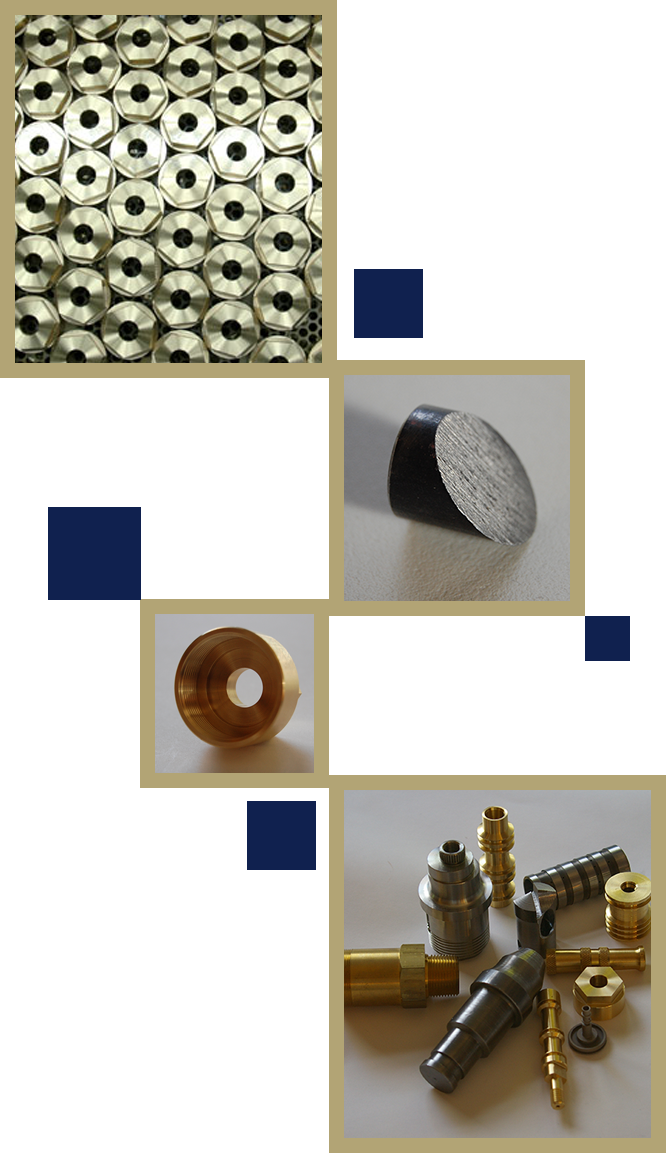

High Volume Precision Machining

Looking for a reliable partner to produce specialty parts in large volumes without sacrificing quality or speed?

Struggling with multi-step machining operations that slow down production and introduce costly errors?

ORRCO is your solution.

Based in Greensburg, PA, ORRCO specializes in high-volume precision machining for OEMs and manufacturers across industries such as hydraulics, motion control, valves, and electronics. We machine steel, brass, aluminum, stainless steel, copper, plastic, and carbide with tight-tolerance repeatability. Our quality systems are ISO 9001:2015 certified.

Custom Machining Centers for Complex Parts

At ORRCO, we don’t just run parts. We engineer solutions. Our team designs and builds custom machining centers capable of performing multiple operations—milling, grinding, and turning—on a single part. This reduces handling, minimizes error, and accelerates throughput for high-volume production.

Whether you’re scaling up an existing part or launching a new product line, our machining systems are built to deliver cost efficiency, consistent quality, and long-term reliability.

Scalable Production with Proven Results

We support production volumes from 100 pieces to millions, with flexibility for smaller quantities when needed. Our team works closely with sourcing professionals and engineers to meet demanding specifications, tight deadlines, and evolving project needs.

Visit our Capabilities and Equipment List pages to explore our full range of services. You can also Contact Us to discuss your next project.

Quality Control

Every job order at ORRCO is monitored from start to finish to ensure compliance with your specifications. Our documented QA system and rigorous inspection protocols are designed to catch issues early and maintain consistency across large production runs.

We ensure quality through:

- Use of certified raw materials including steel, brass, aluminum, stainless steel, copper, plastic, and carbide

- Full traceability from raw material to finished part

- Programmable visual measuring machines for in-process and final inspection

- Regular calibration of all machining and inspection equipment

- ISO 9001:2015-certified quality management systems

Once designs and samples are approved, we maintain volume production schedules and delivery dates through ORRCO’s integrated management systems. This ensures your parts arrive on time and meet your expectations.

REQUEST A QUOTE TODAY