Enhance Your Garden Experience with Orrco’s USA-Made Brass Hose Adapter Connector

May 15, 2024

Why Precision Matters in Every Sector

August 26, 2025When you’re sourcing critical components for your next project, your choice of manufacturing partner can make or break your timeline—and your budget. Tolerances, finishes, compliance standards, and lead times all matter. So how can engineers and buyers separate the top-tier shops from the rest? Start with these five questions.

1. Do They Understand Your Industry?

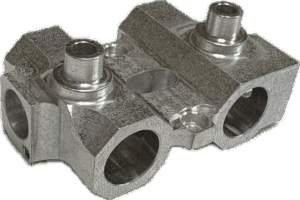

It’s not just about cutting metal—it’s about understanding the context around your part. A machining partner with industry-specific experience, like medical, valve, or electrical components, brings insight into relevant standards, tolerances, and design nuances that others might miss. That knowledge translates into faster approvals, fewer revisions, and parts you can trust.

2. Can They Meet Your Tolerance and Quality Standards Consistently?

You’re not just sourcing a component—you’re ensuring performance. Ask about real-world tolerances they hold day in and day out, not just what’s listed on a spec sheet. Dig into their quality control processes, inspection equipment, and certifications. A great shop won’t just meet the spec; they’ll deliver peace of mind.

3. Are They Transparent About Capacity and Lead Times?

A common pain point in machining relationships is overpromising. The best partners are candid about capacity and delivery schedules. Look for those who offer realistic lead times, communicate proactively, and—when needed—ship partial orders to keep your project moving without delay.

4. Are They Invested in Precision Equipment and Skilled Talent?

Top-tier results require the right tools—and the right team. From CNC turning to multi-axis milling, their equipment lineup speaks volumes about what they can achieve. But even more important? The people operating those machines. Look for signs of investment in tooling, maintenance, and training—it’s a reflection of their reliability.

5. Will They Provide Design Feedback?

A reputable machining partner will evaluate your part’s design for manufacturability. Their technical review of drawings can help ensure that your component is optimized for efficient production—reducing costs, eliminating potential issues, and meeting performance standards before production begins.

Looking for a Reliable Machining Partner?

At Orrco, we support engineers and buyers through every phase of production with proactive insights, reliable lead times, and unmatched precision. If you’re evaluating machining partners, let’s start a conversation. Explore our precision machining capabilities.